The development of illumination

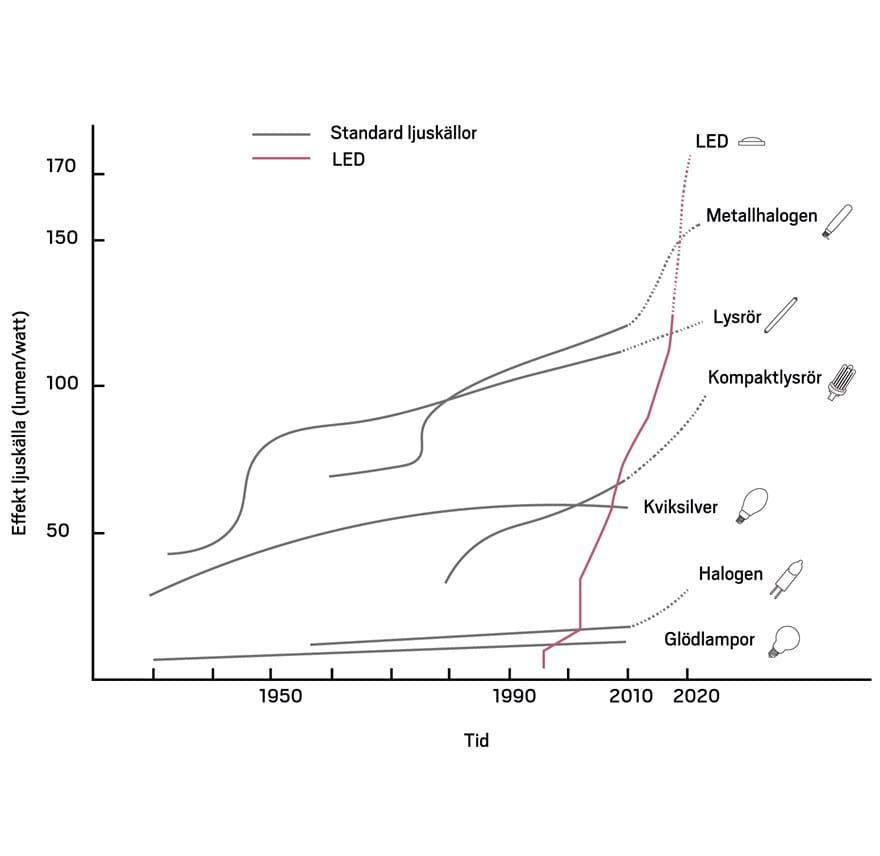

LEDs, or Light Emitting Diodes, are the greatest technical shift since the light bulb and they have revolutionised the illumination industry over the latest 10 years. This shift and its development has taken place at a more rapid and broader pace than anyone could foresee or even dream of - today we know that the light source of the future is LED. LEDs already produce more light/watt than the best fluorescent tubes and metal-halide lamps.

The advantages of LED are great and abundant, while the disadvantages are few. The argument of a 90% saving on energy and more than 50 times the lifetime speaks for itself. Today there are LEDs with a luminous efficacy and colour rendering so good it is possible and economical to replace most other types of light sources and luminaires with LEDs, from the smallest light source in a home environment to all the most common office and street lighting.

We are approaching a total changeover to LED solutions. The industry forecasts that LED luminaires will stand for more then 95% of the market in Europe by the year 2020.

Technology has enabled endless possibilities but also some difficulties because, as always with new technology, there are many pitfalls. Pleasingly, today there is a standard that defines how facts for LEDs and LED luminaires are to be reported. We always provide all luminaire data such as lifetime, lumens and power consumption for a complete luminaire in normal usage conditions, precisely as the standard prescribes. Make sure you ask others if they do the same so you don’t compare apples and pears!

The information given on the following pages is an attempt to describe how LED technology works and explain some of the technical terms used in the industry. This information is based on the knowledge and practical experiences of LEDs that Hide-a-lite has gathered over 10 years. It has been written for LEDs in general and for our product range specifically. In addition to the luminaire standard, facts have been gathered from Värt att veta om LED, LED för belysning inom- och utomhus and LJUSA mallen, published by Belysningsbranschen & Ljuskultur. We can also recommend these to gain in-depth knowledge in the subject.

All the information in this publication should be regarded as general and used as a guide. For more precise information, we refer you to the product description of each product at www.hidealite.com.

LED - Light

The light created is monochromatic and the colour is determined by the dominating wavelength. LEDs are available in the colours red, orange, yellow and blue. LED light is free from IR and UV radiation.

White LED

White light is created by mixing the three colours red, green and blue (additive colour mixing) or giving a blue LED a yellow or orange luminescent material (phosphorous), which changes part of the radiation to yellow light so that the result will be white light, just as with fluorescent tubes and low-energy light sources (conversion). Phosphorous conversion is absolutely the most common method, mainly because it is cheaper but also because it gives a better and more even colour rendering.

The development of illumination

Today, white LEDs are divided into three main groups:

Warm white: <3300k white:="" 3300-5300k="" cold="" white:="">5300K

Characteristics - Diode function and design

To protect against external impingement and to enable an electrical connection, the LED is sealed in a casing with an angle of illumination of 140–160 degrees, giving a simpler light control than omnidirectional light sources. In order to work, the LED is mounted on a PCB enabling and easy electrical contact and which conducts away heat at the same time. An LED has not electrical resistance of its own, which means a current limiter must be included in the electrical circuit. This requires direct current with the correct polarity via a driver, since it only conducts electricity in one direction from positive to negative. The amperage through the LED determines how much light is produced.

LED modules

LED colour/Colour temperature

The colour temperature of a light source is measured in degrees kelvin (K) and describes the colour of a light source from warm red colours to cold blue in comparison to the colour of a metal filament (a black body) when being heated to different temperatures. From red at low temperatures via white to blue at high temperatures. Stearine candles have a light temperature of around 1500K, an incandescent bulb 2700K, a 12V halogen bulb 3200K, compare a white LED.

Colour rendering (CRI)

Colour rendering is given as a CRI index and specifies how well a light source reproduces colours on a scale from 0 to 100% compared to a reference light source and is an average value of 8 standard colours. Compare with a fluorescent tube where 830 stands for 80% Colour Rendering Index (CRI) and a colour temperature of 3000K.

White LEDs generally have very good colour rendering. Warm white and white have a CRI of between 80 and 95, and cold white somewhat less, between 70 and 85, and can therefore measure up to most common light sources.

Colour rendering of LEDs is usually perceived as significantly better than what the CRI specifies. Relying more on your own eyes and testing the light in place is good advice.

----

MacAdam 1-3 SDCM

Suitable for environments with high demands on uniformity and large white walls

MacAdam 3-5 SDCM

Suitable for most indoor environments

MacAdam 5-7 SDCM

Mainly for outdoor environments

Light quality

Colour temperature (CT)

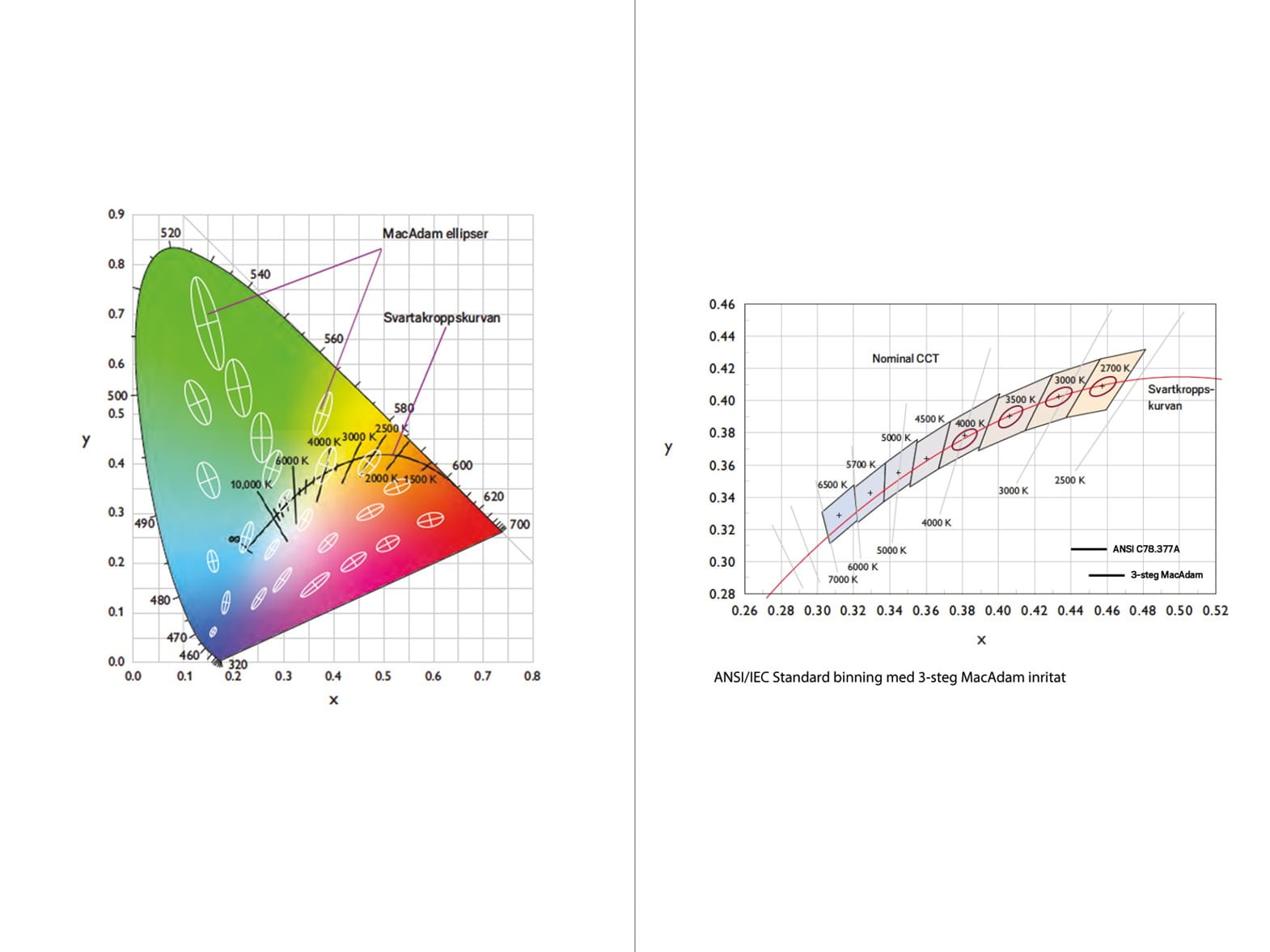

In the CIE Colour Triangle, used to define colour temperature, there is a black line/curve, black body curve (Planck’s curve), which specifies exactly with which LED colour a filament lights/radiates at a given temperature in kelvin (K). An incandescent light source heated up to the same temperature will be at exactly the same place on the curve and will glow with the same colour temperature and hue.Correlated colour temperature (CCT) and hue

Binning white LEDs

For warm white LEDs, the standard allows a variation of up to 500K, which gives clearer differences in colour while we normally accept 100-200K, a variation that normally cannot be perceived with the naked eye.

Colour deviation SDCM

In order to show this, it is now specified as a complement to the correlated colour temperature in kelvin (K), also colour tolerance, which is a measure of the beam angle in LED colour and shows the differences in colour temperature and hue. Specified according to luminaire standard as SDCM (Standard Deviation of Colour Matching) of the size MacAdam-ellipses in a CIE colour triangle.

By selecting luminaires with a narrow colour distribution, it is possible with LEDs to find lighting solutions where no differences in LED colour can be detected between individual luminaires and where this characteristic remains during its entire lifetime.

One Macadam ellipse (1 SDCM) specifies a variation in colour temperature and hue that the human eye cannot detect. Normally, you can say 1-3 ellipses guarantee the luminaires will be perceived as being the same LED colour even on white wall surfaces. As a comparison, a T5 fluorescent tube has a deviation of 4 SDCM while a compact fluorescent light and low-energy bulbs have up to 7 SDCM, giving clearer differences in colour. The standard specifies a maximum allowed deviation of 7 SDCM

Hide-a-lite has a goal of staying within the 3 SDCM mark, not only during manufacture but also between different manufacture and luminaire series. Costs will be higher but deviation considerably less and we can use bins from the same position in the colour triangle to obtain an equal LED colour every time.

CIE Colour Triangle

A colour triangle with black body radiation curve overlaid together with the guidelines used to establish the correlated colour temperature of a light source. An LED colour can be determined with X and Y coordinates.

NB! Size and orientation varies significantly depending on its position in the colour triangle. Note that for the sake of clarity, the ellipses in this diagram are 10 times actual size.

Lumen output/luminous efficacy

how much light a light source provides in all directions. For directed light sources, the lumen output is measured as a cone of light

with a 90° angle.

Luminous efficacy is a measure of how energy efficient a light source is and is given in lumen per watt (lm/W).

Today there are LEDs with a luminous efficacy of over 150 lm/W and already more energy efficient than all other

light sources. Warm white LEDs normally have a 15-25% lower luminous efficacy than cold white since more light

is filtered away with fluorescent powder (phosphorous). Since an LED gives directed light, its efficiency is also often

much better than what the lumen value indicates compared to normal light sources. In a comparable luminaire with

compact fluorescent light, the loss in the luminaire could be as much as 40-60% of the lumen output, while an LED often

stays between 10 and 20%.

Effects of temperature

The lifetime of an LED and its luminous efficacy is mainly impacted by heat. Factors that affect heat in an LED are amperage, heat conduction and ambient temperature. Since an LED does not generate heat in the form of IR radiation and only some of the energy becomes light, the heat that is generated must be diverted to surrounding parts of the luminaire, which are then cooled down. An increase in heat impacts on LED performance both long and short term. In the short term with a change in colour and reduced luminous efficacy. In the long term with a faster gradual degradation and therefore shorter lifetime.

The affected lifetime is impacted by factors such as:

• Type of LED and quality (manufacture)

• With which amperage it is driven

• Environment and ambient temperature when product was installed

• Driver quality

• Luminaire design and choice of materials

Lifetime (gradual degradation) LED luminaires

According to international standards, the life expectancy of an LED luminaire is given with two values, the life expectancy of the LED module and the life expectancy of the driver. Both values are required to obtain a comparable conception of life expectancy.

From watts to lumens

We are used to choosing light source based on fitting size and number of watts. But with LEDs, two products with

the same wattage can give different amounts of light depending on how it is designed and how it is driven. When choosing an LED,

look at how much light the light source provides (lm). The following explanatory table is published by

the Swedish Energy Agency, which compares older light sources with LED:

All values are approximate. The span is due to different types giving different values. However, the differences cannot

normally be perceived with the naked eye. The lumen of reflector lamps applies within a light cone with 90°

angle of illumination.

LED modules

The life expectancy of LED modules is given as the number of hours (h) when at least a given percentage of the lumen output remains (maintenance factor) in an L value (LX). LEDs for illumination purposes must have at least 70% of their lumen output remaining (L70). Higher values such as (L80) and (L90) can also be specified.

As a complement, a B-value (outage percentage) is given that specifies what part of a population is the maximum to be expected to fall below this value (By). B10 means 10% will fall below (LX) and B50 that half, 50%, will. B50 is described in the standard as Median Useful Life.

Lighting Europe recommends the B-value no longer being used for gradual degradation in order to facilitate comparison between different LED luminaires as an analysis has shown that the difference between a base value of B50 and B10 is so small and that the accuracy is still sufficiently high.

L70 50,000h means that 50% (B50) will light with at least 70% of the lumen output it had at manufacture after 50,000 hours.

L80 50,000h means that 50% (B50) will light with at least 80% of the lumen output it had at manufacture after 50,000 hours.

Since gradual degradation is negatively affected very rapidly as the heat surrounding the LED increases, measurement is complemented with ambient temperature (Ta) and should agree with that which applies at normal operating conditions. If no value is given, the data at normal room temperature of 25°C applies.

L70 50,000h Ta 25°C means at least 50% will light with at least 70% of the original lumen output at an ambient temperature of 25°C after 50,000 hours.

We always specify the luminous flux and life expectancy measured on the luminaire under actual operating conditions and current room temperature

LED luminaires/Drivers

Driver degradation is included in the standardised report of the LED luminaires’ life expectancy. The driver life expectancy is reported separately for complete LED luminaires and is given in hours with a degradation in per cent. 50,000h/10% means that a maximum 10% of drivers will stop working during the specified lifetime (0.2% per 1000h). Driver life expectancy is dependant on its design, quality of components and ambient temperature when in use.

Recommendations are based on ”Evaluating performance of LED based luminaires” published by Lightning Europe, supported by international product standards IEC 62722-2-1 – LED luminaires for general lighting and IEC 62717 – LED modules for general lighting.

Installing LEDs

As with all installations, it is essential to use the correct wire type and dimension if the installation is to work well and be safe. When it comes to LED installations, there are a few more points to be aware of:

Use only drivers intended for use with LEDs. Nearly all LEDs are dependent on polarity and since we work with direct current it is essential to keep + and - separate.

Constant current LEDs driven with e.g. 350mA or 700mA must also be connected in series from + to -

Most LED modules are colour coded. If connected with the incorrect polarity, the LEDs will not light up and can be damaged permanently. (+) Red, Brown or as marked. (-) Blue, Black or as marked

Wattage

Precise values can be found on the product sheet for each product. For LEDs driven with constant voltage, the wattage (W) and amperage (A) are calculated in the same way as is usual for “low-voltage illumination”

Drivers

In order to guarantee good operation and long life of LED products, it is essential to always use good quality drivers intended for LEDs so that they are protected against overvoltage, overcurrent, overload and short circuiting. If drivers other than those supplied or recommended by Hide-a-lite are used, they must always include the following protection.

Two types of LED

Constant voltage

Built-in current reduction driven with e.g. 10V, 12V or 24V, such as LED strips, light chains and LEDs for decorative purposes. Parallel connection is done here and dimensioning is controlled by the total power output.

Without built-in current reduction driven with e.g. 350mA and 700mA, such as LED downlights with the highest lumen output for illumination. Series connection applies here and dimensioning is controlled by the total secondary voltage/output.

Two types of driver

Constant voltage

Electronic DC voltage converter, e.g. 10V, 12V or 24V.

Constant current

Electronic constant current converter, e.g. 350mA and 700mA. Both types of driver are today available both as non-dimmable and dimmable using most light regulation techniques.

Today, there are a number of LED products on the market with integrated drivers for direct connection to 230V, for example replacement light sources with GU10 or E27 base. These cannot always be controlled but today, there are many products on the market that can be controlled with standard dimmers.

Regulating LED lighting

Light regulation with the correct technology leads to energy savings, extended useful life and increased lighting comfort. The dimmable LED drivers we recommend use either technology called pulse width modulation (PWM) or current reduction, also called amplitude modulation (AM).

PWM dimming means the power to the LED is cut and thereby a frequency turns it on and off. This frequency should not be lower than 300Hz when regulating to avoid flicker.

AM dimming means lowering the amperage to the LED. This technology reduces the risk of flickering. Both these technologies normally mean the level of light is reduced without a change in colour, can be controlled with most light regulating systems, phase dimming, phase impulse, DALI, DSI, DMX, 1-10V, etc.

Wire lengths

Halved amperage/power or doubled conductor area = more than double the conductor length.

With a 15W load and conductor area of 0.5mm2, the conductor length can be 8m for 12V and 25m for 24V.

The risk of EMC disturbance is increased for dimmable drivers and you have to be especially careful to follow manufacturer recommendations and choose high-quality drivers. A good way of reducing or avoiding disturbance is to use screened and/or duplex cable.

Economical advantages

Environmental advantages

The high energy efficiency and long useful life means the total impact on the environment is small, since energy consumption is low and fewer light sources need to be replaced and go to recycling. Neither are insects active at night disturbed by LED light.

• LED light is monochromatic and has a different character to usual light sources

• Relatively expensive to purchase but with its low energy consumption and long useful life, they pay for themselves in just a few years.

• White LEDs still have some colour deviations and these shifts in colour must be considered

Important to remember

The useful life of an LED is affected mostly by heat (ambient temperature). Make sure cooling and ventilation is as good as possible and always follow the manufacturer’s minimum recommendations. Always use drivers of good quality intended for use with LED modules.

Take care to ensure correct polarity when installing. If connected with the incorrect polarity, LEDs will not light up and may be permanently damaged, often after only a few seconds.

Our products have a narrower sorting than standard in the industry in order to guarantee as small a deviation as possible. Despite this, there is still a risk of deviations that can be seen with the naked eye. It is therefore important to test the lighting installation when there are high demands on uniformity.

Always check how the manufacturer has specified useful life, if it is related to degradation and in normal operating conditions, so that you are comparing apples with apples. There are still many suppliers who incorrectly specify LED life expectancy as 100,000 hours or more without relating to the standard’s maximum degradation requirement.

All information in this document should only be regarded as general and serving as a guideline. Precise information on each product is available on a product sheet and the installation instructions on our website, www.hidealite.se.

LEDs have many advantages over normal light sources:

Extremely small and thin

The light has no IR or UV radiation

LEDs work well or better in cold environments, in refrigerators their useful life increases considerably in comparison with room temperature

Very long useful life

Insensitive to knocks and vibration

Easy to drive, start directly with full effect and can be regulated easily and flicker-free from 0-100%

Life expectancy not impaired by being switched on and off.

LEDs have a high luminous intensity and can be controlled easily with plastic lenses or small reflectors with small losses

Do not contain mercury or other heavy metals

Powered with low voltage - simpler and safer installation